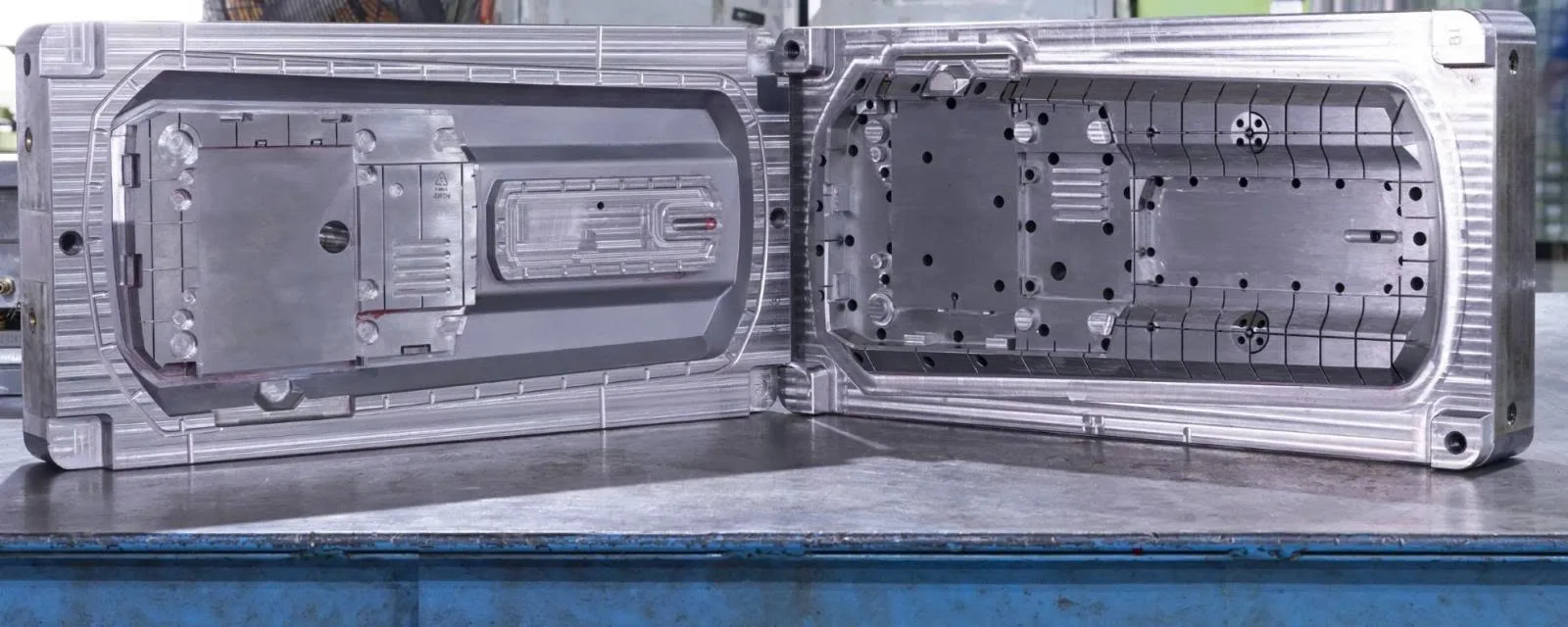

In the modern plastics industry, precision plastic molds are the decisive factor in product quality and stability. Zeng Hsing is a prestigious provider of precision plastic mold design and fabrication, equipped with an advanced machinery system. With a rigorous control process and a commitment to quality, Zeng Hsing delivers optimized mold solutions for enterprises across various industries. We are a trusted partner for businesses seeking high-quality, durable plastic molds that meet international standards.

What is a Precision Plastic Mold?

A precision plastic mold is a specialized tool used in the plastic injection molding process. It is manufactured with extremely tight tolerances, typically ranging from ±0.01 mm to ±0.05 mm, depending on the specific product requirements. These molds are critical in modern production lines as they directly determine the quality and consistency of the final product.

Key Criteria for High-Quality Precision Molds:

♦ High Durability and Longevity: Designed to withstand hundreds of thousands to millions of injection cycles.

♦ Superior Surface Finish: The mold cavity surface is highly polished to ensure aesthetic excellence and minimize surface defects.

♦ High Geometric Accuracy and Fit: Perfectly engineered for intricate parts that require high levels of sophistication.

♦ Stable Ejection Performance: Ensures consistent part removal, significantly reducing defects such as warping, denting, or deformation.

Thanks to these characteristics, precision plastic molds are widely utilized in manufacturing products that demand high stability and consistency.

>>>> Xem thêm: Nhận gia công ép nhựa TPHCM số lượng lớn, độ chính xác cao

The Role of Precision Plastic Molds in Industrial Production

In many industries, plastic products play an irreplaceable role. From small components like connectors, caps, and housings to complex technical parts, all require injection molding from high-quality standard molds.

Precision plastic molds directly impact:

» Production Line Efficiency: High-quality molds ensure fast and stable cycle times.

» Defect Rate: Quality molds significantly reduce scrap rates and overall production costs.

» Product Consistency: This is critical in the electronics and technical equipment industries.

» Aesthetics: Ensuring smooth surfaces with no flash (bavia) or burn marks.

Aboved are reasons why businesses need to partner with professional mold manufacturers to ensure their product output meets international standards.

>>>> Xem thêm: Đơn vị đúc nhôm áp lực Việt Nam giá tốt, chất lượng cao

Common Applications of Precision Plastic Molds

Precision plastic molds are essential across almost every manufacturing sector:

• Electronics Industry: Production of housings, covers, connectors, and micro-sized plastic components.

• Home Appliances: Accessories for air conditioners, rice cookers, vacuum cleaners, and various internal plastic parts.

• Automotive & Motorcycle Industry: High-strength plastic components, interior trim details, handles, and protective housing assemblies.

• Office Equipment & Industrial Machinery: Sewing machine housings, control panels, and interlocking components.

• Medical Devices: High-precision plastic parts requiring absolute stability and strict compliance.

Each industry demands different technical standards for its molds; therefore, the experience and capability of the mold manufacturer are of paramount importance.

>>>> Xem thêm: Gia công ép nhựa công nghiệp theo yêu cầu, chuẩn kỹ thuật

Zeng Hsing – A Trusted Leader in Precision Plastic Mold Design and Fabrication

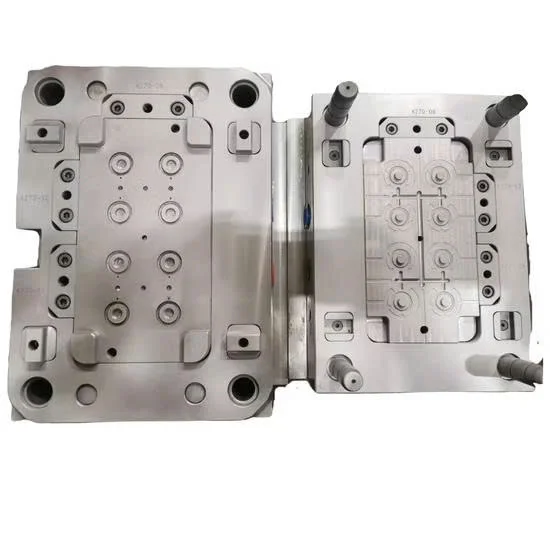

Zeng Hsing operates a modern mold development center equipped with high-precision CNC, EDM, Wire-cut machines, and CMM (Coordinate Measuring Machines), ensuring micron-level accuracy for every mold component. Our engineering team brings years of expertise in designing complex mold structures, optimizing melt flow, and guaranteeing mold longevity for high-volume mass production.

Core Strengths of Zeng Hsing

√ Strong Design Capability: Expertly handling multi-cavity molds, complex slider/lifter mechanisms, and products with tight tolerances.

√ Integrated Production: A seamless end-to-end process—from Mold Design → Fabrication → Mold Testing (T1) → Injection Molding—optimizing costs and significantly shortening lead times.

√ Rigorous Quality Control: A step-by-step inspection process at every stage of fabrication to ensure stable performance and long-term durability.

√ Commitment to Lead Time: On-time delivery with dedicated maintenance support throughout the production lifespan.

Factors Affecting the Cost of Precision Plastic Molds

The cost of fabricating a precision plastic mold depends on various technical factors. Since each plastic product has unique requirements for material, durability, structure, and finishing, the mold price is calculated based on the following specific criteria:

Mold Materials

– Steel grades( P20, H13, S136, or NAK80) are selected based on the desired hardness, corrosion resistance, and polishability.

– Mass Production Molds: For high-volume production, premium high-grade steel is used to ensure durability, leading to a higher initial investment.

– Prototyping or Low-Volume Molds: For smaller batches or testing, softer or pre-hardened steel can be used to reduce material and machining costs.

Product Complexity

The more intricate the product design - including small details, sharp corners, reinforcement ribs, or complex mechanisms like sliders and lifters - the higher the cost:

– Extended Design Time

– Intricate Machining

→ The mold price increases proportionally with the level of complexity.

Number of Cavities

– Single-cavity molds are more cost-effective for low-volume production.

– Multi-cavity molds significantly boost productivity and lower the part's unit price. However, they demand much higher precision in the runner system and cooling channels, leading to increased fabrication costs.

Tolerance and Accuracy Requirements

– Tight Tolerances: a precision of ±0.01 mm to ±0.03 mm

– Products intended for precise interlocking or mechanical assembly.

– Requirements for high-gloss polishing or specific textures

All of these factors impact the mold price as they demand more extensive fine-machining time.

Product and Mold Size

Large molds require a greater volume of steel, extended machining hours, and large-scale cutting tools. Consequently, the fabrication cost increases proportionally with the physical dimensions of the mold.

Mold Trials and Adjustment Requirements

The number of trial runs (T1, T2, T3) required to achieve the final approved sample also impacts the total cost.

Contact Zeng Hsing for a Precision Plastic Mold Quotation

If you are looking for a precision plastic mold quotation for your production project, contact Zeng Hsing today. Our expert engineering team specializes in mold design and fabrication and is ready to support you with:

√ Cost-Optimization Consulting

√ Detailed & Transparent Quotations

√ Technical & Material Analysis

√ Optimized Mold Solutions

Contact Zeng Hsing today for a fast and professional precision plastic mold quotation!

ZENG HSING VIET NAM

Address: Lot 28 VSIP II-A, Street 28, VSIP II-A Industrial Park, Vinh Tan Ward, Tan Uyen City, Binh Duong Province, Vietnam.

Phone: (+84) 0355 846 965 (Mr. Nghĩa) / (+84) 0362 476 478 (Mr. Nam)

Email: nghia_duong@zenghsing.com.vn / nam_vu@zenghsing.com.vn

Website: zenghsing.vn

Tìm kiếm có liên quan

Khuôn đúc nhựa

Khuôn đúc nhựa PVC

Khuôn mẫu ép nhựa

Gia công ép nhựa