The manufacturing of thin, complex, and highly accurate aluminum components has become an essential requirement in modern industry, particularly across the automotive, electronics, industrial machinery, and home appliance sectors. High-Pressure Die Casting (HPDC) is the preferred methodology, favored for its capability to produce thin, uniform components with a fine surface finish and tight tolerances. So, what enables High-Pressure Die Casting to achieve such precision for these thin-walled parts?

OPERATIONAL MECHANISM OF HIGH-PRESSURE DIE CASTING

High-Pressure Die Casting (HPDC) operates based on injecting molten aluminum into a steel die under high pressure. When the molten aluminum fills the die cavity, the high pressure helps the metal flow uniformly, resulting in a smooth component surface, even across thin walls or complex grooves.

The conditions required for high-accuracy production of thin components include:

» High-precision, High-quality Steel Dies: Ensures the component's geometry remains stable and free from distortion, resulting in a fine surface finish and tight tolerances.

» High-Pressure Injection Machine and Rapid Injection Velocity: Helps the metal fill the die before solidification, mitigating defects such as shrinkage, gas porosity, or hot tearing.

» Temperature and Pressure Control: The alloy temperature and injection pressure must be stable to ensure the final product achieves the desired mechanical properties and dimensional integrity.

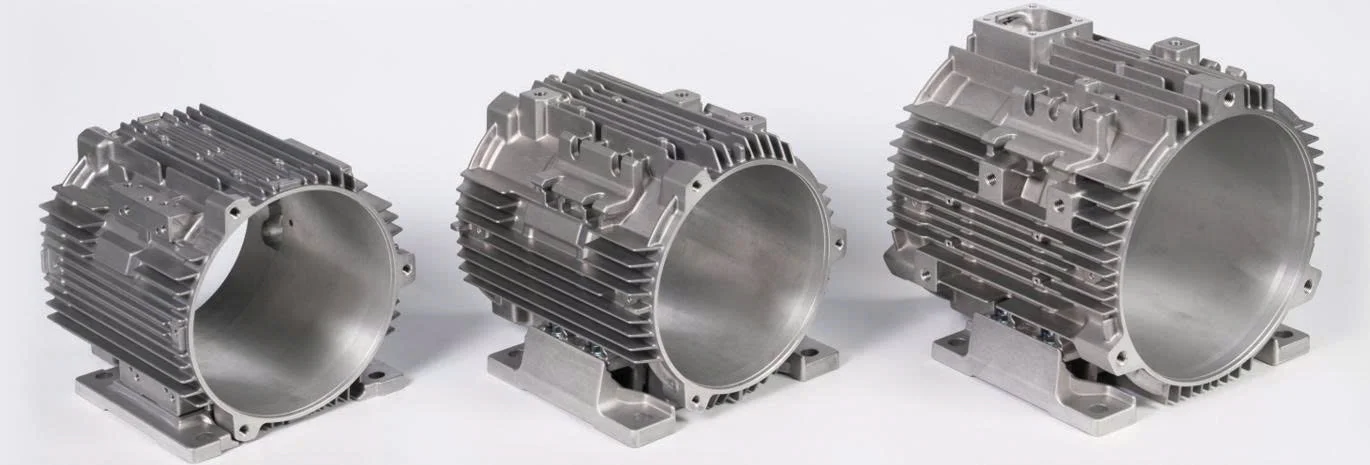

Thanks to this mechanism, High-Pressure Die Casting can produce components with very thin wall thicknesses, ranging from 1–2 mm, while still ensuring high dimensional stability and structural integrity.

CRITICAL FACTORS FOR ACHIEVING HIGH ACCURACY IN THIN-WALLED COMPONENTS

To produce thin components using High-Pressure Die Casting, manufacturers must consider several critical factors:

Optimized Tooling Design (Die Design)

– Ensuring optimal flow distribution and venting systems to prevent air entrapment and gas porosity.

– Optimizing the component's geometry to minimize shrinkage and warpage during the cooling process.

Appropriate Aluminum Alloy Selection

– Aluminum alloys such as ADC12, A380, or A356 are common in die casting, helping to balance castability (fluidity), strength, and mechanical properties.

– The correct alloy selection ensures uniform thin sections and mitigates the risk of cracking and porosity.

Strict Production Process Control

– The alloy temperature, injection pressure, holding time, and cooling rate must be continuously monitored

– Effective control prevents component distortion, shrinkage, or the appearance of defects.

By combining these three factors, High-Pressure Die Casting not only creates thin components but also achieves high accuracy, meeting stringent technical standards.

OUTSTANDING ADVANTAGES OF HPDC FOR THIN-WALLED COMPONENTS

Compared to other aluminum casting methods, High-Pressure Die Casting (HPDC) offers distinct advantages, particularly when producing thin-walled components:

• High Dimensional Accuracy and Tight Tolerances: Components are nearly net-shape upon die opening, reducing or eliminating the need for post-casting machining (secondary operations).

• Fine Surface Finish and Uniform Quality: The resulting product can be used directly or proceed to painting or anodizing with minimal additional surface preparation.

• Complex Geometry Capability: HPDC permits the manufacturing of components featuring grooves, reinforcing ribs, holes, and complex profiles while remaining thin and lightweight.

• Mass Production Efficiency: The process is suitable for high volumes, ensuring uniformity, and optimizing both cost and production lead time.

Due to these advantages, High-Pressure Die Casting is the ideal solution for thin-walled components requiring high accuracy and consistency in modern industrial manufacturing.

LIMITATIONS AND CONSIDERATIONS FOR THIN-WALLED High-Pressure Die Casting

Despite offering numerous benefits, the production of thin-walled components necessitates careful attention:

– Potential for Gas Porosity: If the metal injection process is not optimally controlled, air bubbles may become entrapped, leading to porosity which compromises the component's mechanical integrity.

– Strict Requirements for Die Design and Alloy Selection: Thin components are highly sensitive to warpage or cracking if the tooling (die) or alloy composition is unsuitable.

– High Initial Capital Expenditure: Steel dies, high-pressure injection machinery, and quality control systems require substantial capital investment, making the process best suited for medium-to-large production volumes.

Therefore, before selecting High-Pressure Die Casting, it is essential to ensure the component design is optimized, conduct thorough prototyping (sampling), and perform First Article Inspection to verify product quality.

HIGH-PRESSURE DIE CASTING – THE OPTIMAL SOLUTION FOR THIN-WALLED AND CONSISTENT COMPONENTS

High-Pressure Die Casting is the most efficient methodology for producing thin-walled, high-precision, and dimensionally consistent components. Through optimized tooling design, selection of the appropriate alloy composition, and stringent process control, manufacturers can fabricate intricate, thin-sectioned parts while ensuring superior mechanical properties and an excellent surface finish.

This represents the ideal manufacturing solution for enterprises requiring lightweight, accurate, aluminum components for high-volume production. Strategic investment in high-quality HPDC technology and processes yields long-term benefits in terms of maximized production throughput, improved product quality, and optimized cost-efficiency.

ZENG HSING VIET NAM

Address: 28 VSIP II-A, No.28 street, KCN VSIP II-A, Vinh Tan ward, Ho Chi Minh city, Vietnam

Phone: (+84) 0355 846 965 (Mr. Nghia) – (+84) 0362 476 478 (Mr. Nam)

Email: nghia_duong@zenghsing.com.vn / nam_vu@zenghsing.com.vn

Website: zenghsing.vn