Aluminum Die Casting Production

Aluminum Die Casting Production

Aluminum Die casting Production Factory

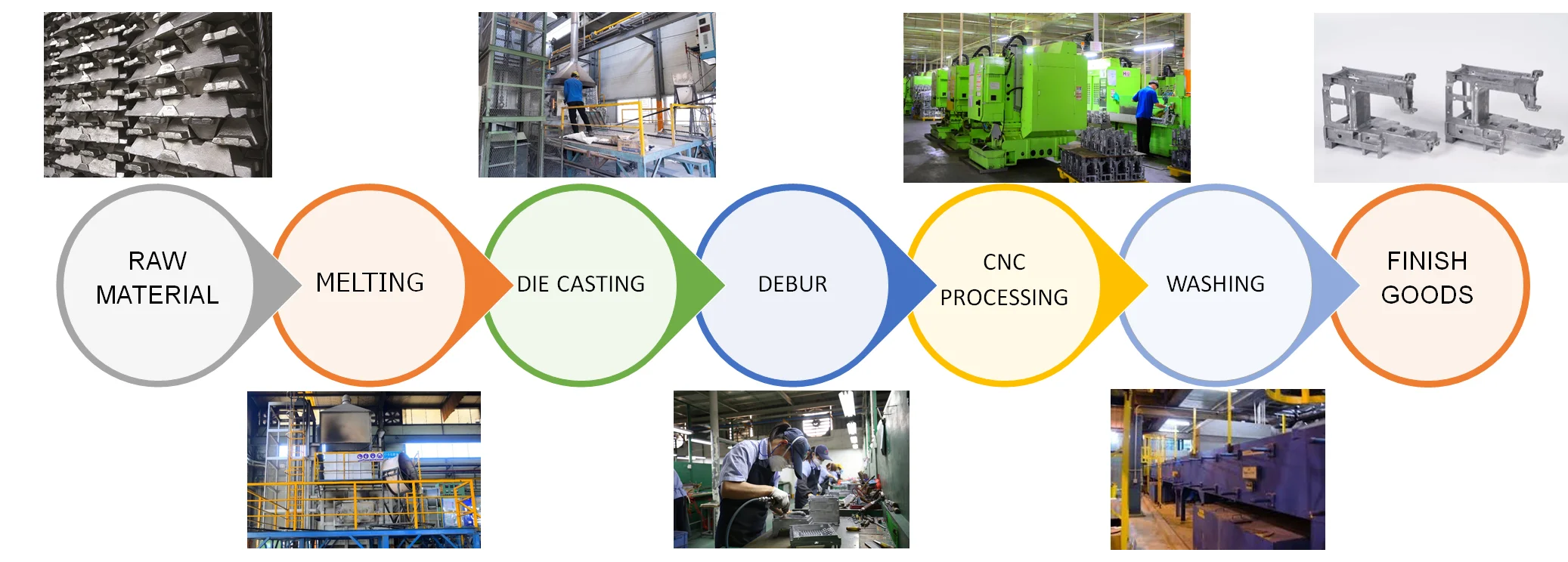

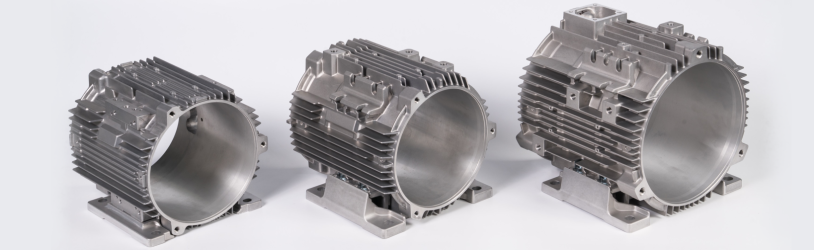

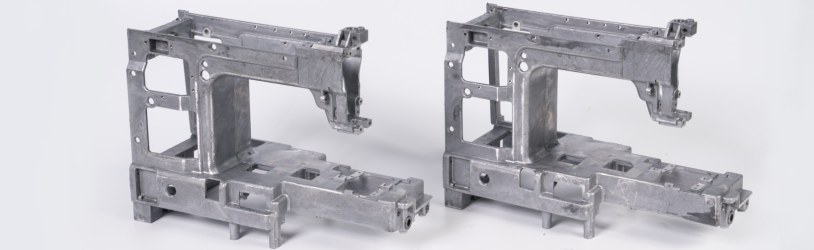

Aluminum Die-Casting – High Efficiency & Precision: Our aluminum die-casting process ensures high-quality, precise, and efficient production, minimizing the need for additional machining. This enhances metal utilization, reduces processing time, and accelerates mass production. Widely used in automotive, bicycles, appliances, furniture, 3C electronics, aerospace, and machinery, aluminum die-casting replaces traditional iron and steel to meet lightweight and cost-effective manufacturing demands.

Aluminum Die casting Production Factory

Product Quality Assurance – Precision & Reliability: Our advanced precision die-casting technology ensures consistent, high-quality production with strict process control at every stage. We utilize state-of-the-art automated equipment such as Toshiba and Toyo die-casting machines, LPG-fueled melting furnaces, and an automated track system for optimized efficiency. With rigorous quality checks throughout the production line, we guarantee that every product meets customer specifications and industry standards

Aluminum Die casting Production Factory

| Aluminum Melting |

|

|

1,000 Tons | 9 Machines |

| Die casting, Sand blasting, Liquid/Powder, Coating |

|

|

250T – 1,000 Tons | 16 Machines |

| CNC processing |

|

|

196 Machines |

Our Capacity

| Custom and small MoQ production | Equipped with Al furnaces, die-casting, and CNC processing capabilities, can meet customer requirements. |

| Certifications and Standards | Quality is controlled in compliance with ISO 9001:2015, and other certifications. |

| Material | Supported aluminum alloys include ADC12, A380.1, AC44000, AC47000, and other die-castable alloys based on customer requirements. |

| Diameter and Length | Custom dimension according to client demand. |

| Practical Applications and Benefits | Ensure enhanced performance and quality for several industrial, such as Motor, Automotive, garment Industry. |