High-Pressure Die Casting is a manufacturing technology that produces aluminum components by injecting molten aluminum into a steel die under high pressure, resulting in products that are precise, durable, and dimensionally consistent. This methodology is widely applied across diverse industrial sectors, including automotive, electronics, machinery, and industrial equipment. Leveraging its advantages—namely being lightweight, highly durable, material-efficient, and suitable for high-volume manufacturing— High-Pressure Die Casting has become the optimal solution for modern enterprises.

INTRODUCTION TO HIGH-PRESSURE DIE CASTING

In modern industry, the production of accurate, durable, and lightweight aluminum components is a leading priority. High-Pressure Die Casting is one of the most effective solutions, facilitating the creation of aluminum components with high dimensional accuracy and a fine surface finish. This technology is broadly applied across various sectors, including automotive, electronics, industrial machinery, and home appliances.

Unlike traditional casting methods, High-Pressure Die Casting utilizes high pressure to inject molten aluminum into a steel die, resulting in components that are dimensionally uniform, highly precise, and material-efficient. Due to these advantages, an increasing number of enterprises both in Vietnam and globally are prioritizing the use of High-Pressure Die Casting technology in their manufacturing operations.

High-Pressure Die Casting OPERATIONAL PRINCIPLES

The fundamental High-Pressure Die Casting process involves melting the aluminum alloy, injecting the molten aluminum into a steel die under high pressure, holding the pressure/cooling the metal, and extracting the finished component. Depending on the equipment utilized, High-Pressure Die Casting is categorized into two main types:

• Cold Chamber: The molten aluminum is first loaded into a cold chamber, then injected into the die. This method is suitable for aluminum alloys characterized by a high melting point.

• Hot Chamber: The molten aluminum is contained directly within the hot chamber/furnace and injected into the die. This is typically employed for aluminum alloys with superior cast ability (fluidity).

The application of high pressure ensures the resulting aluminum components achieve high dimensional accuracy and thin walls, while mitigating typical casting defects such as porosity, shrinkage, or hot tearing. Furthermore, this process significantly enhances the production cycle speed, effectively meeting large-volume order requirements.

COMMON ALUMINUM ALLOYS UTILIZED IN HIGH-PRESSURE DIE CASTING

High-Pressure Die Casting mandates specific aluminum alloys to ensure components are lightweight, durable, highly accurate, and possess excellent cast ability. Some of the most prevalent alloy types in the industry include:

ADC12 Alloy

– Composition: An Aluminum – Silicon – Copper alloy (Al-Si-Cu) widely utilized.

– Advantages: Features good corrosion resistance, moderate strength, ease of machinability, and resilience to medium mechanical stress.

– Applications: Automotive components, electronic device enclosures, and lightweight mechanical fittings.

A380 Alloy

– Composition: An Aluminum – Silicon – Copper alloy known for its superior stiffness and high load-bearing capacity.

– Advantages: Suitable for heavy-duty components and maintains stability in high-temperature thermal environments.

–Applications: Gearbox housings, automotive sub-frames, and precision mechanical components.

A356 Alloy

– Composition: An Aluminum – Silicon – Magnesium alloy noted for its lightweight properties and high mechanical strength.

– Advantages: Features good heat resistance, excellent thermal conductivity, ease of machinability, and suitability for surface treatment.

– Applications: Precision technical components, heat dissipation components, electric motor housings, and industrial fittings.

CONSIDERATIONS FOR ALLOY SELECTION

• The selection of the appropriate alloy is contingent upon the intended application, required mechanical stress (load requirements), operational temperature, and the working environment.

• Choosing the correct alloy helps to optimize durability, machinability, product service life, and effectively mitigate casting defects during the production process.

KEY ADVANTAGES OF HIGH-PRESSURE DIE CASTING

Utilizing High-Pressure Die Casting offers significant benefits compared to traditional manufacturing methods:

♦ High Component Accuracy: Components feature thin walls, a fine surface finish, and tight tolerances, making the process ideal for complex technical parts.

♦ Material and Cost Savings: Aluminum is utilized optimally, significantly reducing scrap waste and material usage.

♦ Increased Production Speed: High-Pressure Die Casting is suitable for mass production and high-volume manufacturing, effectively meeting large order requirements.

♦ Component Weight Reduction: The process enables optimization of component design and efficiency, which is critically important in the automotive and mobility sectors.

♦High Customization Capability: Tooling design, injection pressure, and temperature settings can be easily adjusted to produce components that meet specific client requirements.

Due to these inherent advantages, High-Pressure Die Casting is regarded as an efficient, cost-effective, and precise manufacturing solution, particularly within the modern industrial environment.

APPLICATIONS OF HIGH-PRESSURE DIE CASTING ACROSS INDUSTRIES

Automotive and Transportation Sector

High-Pressure Die Casting is utilized for manufacturing engine housings, gearboxes, chassis components, sub-frames, and mounting brackets. Aluminum helps reduce vehicle weight, enhances fuel efficiency, and improves thermal dissipation capabilities. For Electric Vehicles, components such as electric motor housings, battery enclosures, and protective battery frames also commonly utilize die-cast aluminum.

Consumer Electronics and Electrical Equipment

Die-cast aluminum is employed to produce device enclosures, machine frames, heat sinks, and intricate electronic components. Aluminum parts feature a fine surface finish, tight tolerances, and complex geometries. This capability facilitates the mass production of modern devices, including laptops, smartphones, telecommunication equipment, and IoT devices.

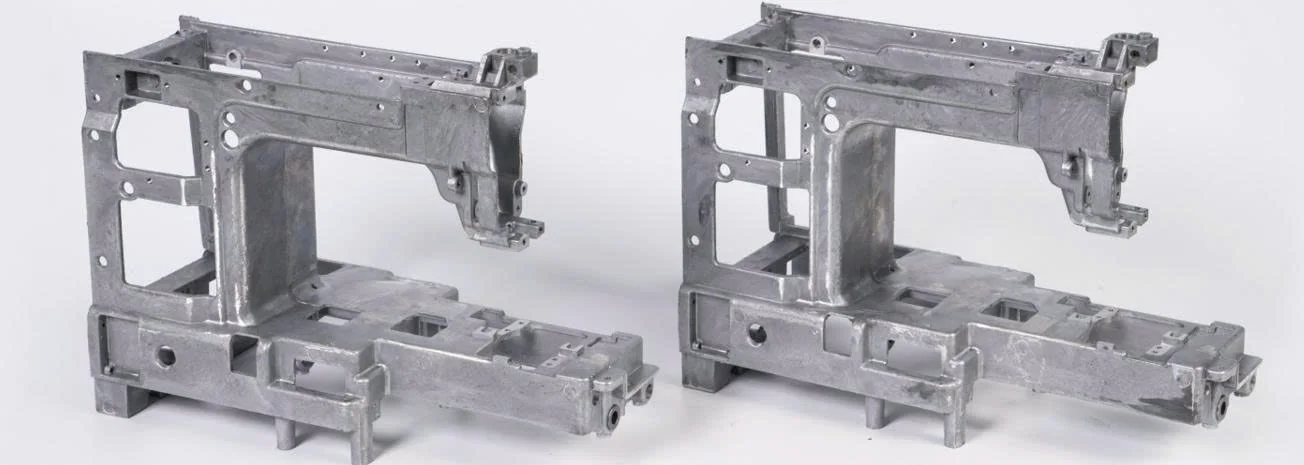

Industrial Machinery and Mechanical Equipment

In the industrial sector, High-Pressure Die Casting is applied to manufacture pump housings, valves, transmission assemblies, machine frames, and gearboxes. Aluminum is lightweight yet durable, maintains dimensional stability, and offers material efficiency. This establishes HPDC as the optimal solution for high-volume production of high-quality mechanical components.

Energy and Specialty Industrial Equipment

Die-cast aluminum is applied in electric motor housings, solar panel frames, turbines, and control devices. Aluminum components are lightweight, exhibit excellent thermal conductivity, are corrosion-resistant, and withstand harsh environments. This makes High-Pressure Die Casting the ideal choice for energy systems and specialized industrial equipment.

Aerospace and High Technology Sector

High-Pressure Die Casting is utilized for manufacturing aircraft components and aerospace fittings due to its low weight, durability, corrosion resistance, and dimensional stability. Aluminum components contribute to overall weight reduction, resulting in fuel savings and enhanced flight performance. High-technology industries also rely on die-cast aluminum for complex mechanical components.

CONSULTATION AND MANUFACTURING WITH ZENG HSING

Given its superior advantages and diverse industrial applications across various sectors, High-Pressure Die Casting is positioned as a highly efficient, precise, and cost-effective manufacturing solution. If you are currently seeking a trusted partner to supply high-quality aluminum components, Zeng Hsing is a specialized High-Pressure Die Casting manufacturer based in Ho Chi Minh City. We boast advanced production lines, a highly experienced engineering team, and processes that adhere to stringent quality standards. Contact us today to consult on the High-Pressure Die Casting solution best suited for your project requirements.

ZENG HSING VIETNAM

Address: 28 VSIP II-A, No.28 street, KCN VSIP II-A, Vinh Tan ward, Ho Chi Minh city, Vietnam

Phone: (+84) 0355 846 965 (Mr. Nghia) – (+84) 0362 476 478 (Mr. Nam)

Email: nghia_duong@zenghsing.com.vn / nam_vu@zenghsing.com.vn

Website: zenghsing.vn