The demand for plastic injection molding contract manufacturing in Ho Chi Minh City is continually increasing as enterprises require high-quality, consistent, and on-schedule production of plastic components. With modern production lines and a highly experienced engineering team, Zeng Hsing is exceptionally well-equipped to handle high-volume orders that demand stringent dimensional accuracy. We provide comprehensive plastic injection molding solutions that optimize costs and ensure quality compliant with international standards. We are the reliable partner choice for businesses in HCMC seeking a professional and specialized plastic manufacturing contractor.

WHAT IS PLASTIC INJECTION MOLDING CONTRACT MANUFACTURING AND ITS IMPORTANCE TO BUSINESSES?

Plastic Injection Molding Contract Manufacturing is the process of using an injection molding machine to create customized plastic components. This is achieved by melting virgin polymer resin and injecting it into a mold. In Ho Chi Minh City, this service has become a vital link in the supply chain for various industries:

• Electronics and Electrical Equipment

• Textiles and Garments, Home Appliances

• Automotive and Motorcycles

• Medical Devices

• Machinery and Industrial Equipment

• Consumer Products

Plastic Injection Molding delivers clear benefits to businesses: rapid production, competitive pricing, high precision, suitable for both mass-market products and complex structures.

>>>> Xem thêm: Gia công ép nhựa công nghiệp theo yêu cầu, chuẩn kỹ thuật

WHY IS ZENG HSING THE PREMIER CHOICE FOR PLASTIC INJECTION MOLDING IN HO CHI MINH CITY?

Modern Factory System – Scaled for High-Volume Production

Zeng Hsing owns a large-scale plastic injection molding facility equipped with modern production lines featuring multiple high-capacity injection molding machines, suitable for everything from small components to complex parts. This system is operated by a highly experienced team of technicians, ensuring:

– High Precision for every component.

– Strict control over critical parameters: Temperature – Pressure – Cycle Time.

– Capability to handle large orders within short lead times.

– Continuous production to meet strict business schedules and deadlines.

Highly Experienced Technical Team

Zeng Hsing is a brand with a long history in industrial manufacturing. We possess a technical team that is:

– Specialized in polymers and plastic materials.

– Proficient in operating various Japanese and Taiwanese injection molding machines.

– Experienced in producing high-precision components.

– Knowledgeable in injection mold design and product quality control.

Consequently, every product delivered meets the required standards: accurate dimensions, correct color, specified durability, and functional requirements for real-world operation.

>>>> Xem thêm: Chất lượng dây chuyền sản xuất Ép nhựa tại Zeng Hsing

DIVERSE MANUFACTURING CAPABILITIES – MEETING ALL REQUIREMENTS

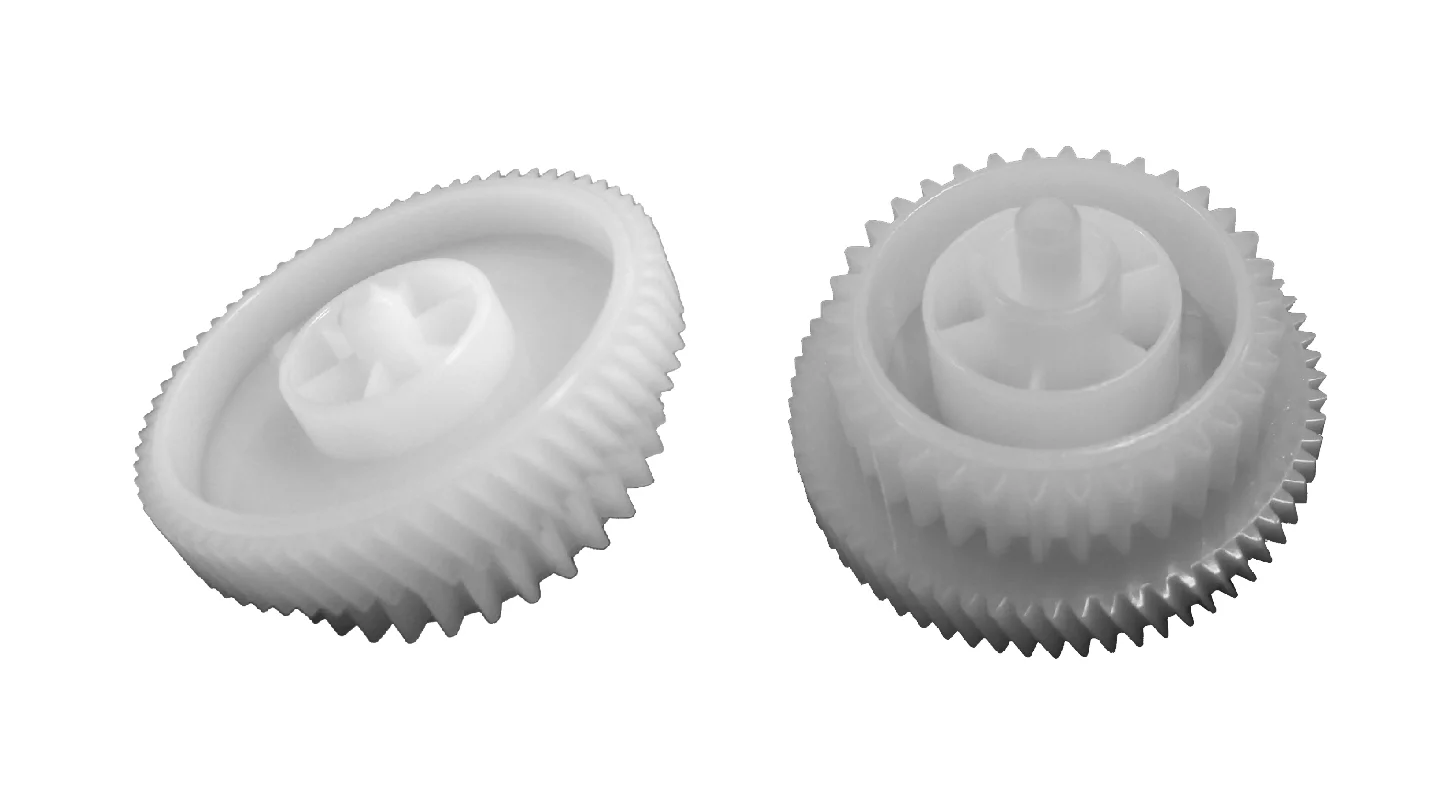

Zeng Hsing currently accepts contract manufacturing for the following plastic product groups:

• Single Plastic Injection Products

– Simple, single-color plastic components with high durability.

– Plastic products with custom colors or printed colors as required.

– Engineering plastics featuring complex shapes and multiple characteristics: load-bearing, heat-resistant, wear-resistant, etc.

• Functional Plastic Assembly

We possess the capability to deliver fully assembled finished products through the integration of:

– Injection molded components from our factory.

– PCB boards

– Electrical wiring (sourced from Foremost Factory – within the same group).

– Additional customer-supplied components.

This capability helps businesses reduce production costs, simplify the supply chain, and shorten time-to-market.

STRICT QUALITY CONTROL ACCORDING TO INTERNATIONAL STANDARDS

The QC and QA system at Zeng Hsing is established based on a stringent process, including:

– Incoming Material Inspection procedures.

– In-process product testing according to each production cycle.

– Testing for durability, stress resistance, color consistency, and dimensional accuracy.

– Transparent quality reporting as requested.

Consequently, plastic products consistently achieve high precision, making them especially suitable for sectors demanding stringent standards, such as electrical and electronic equipment.

>>>> Xem thêm: Đơn vị gia công chế tạo khuôn nhựa chính xác chất lượng cao

COMPETITIVE PRICING – OPTIMIZED FOR BUSINESSES

Thanks to our large factory scale and automated production, Zeng Hsing offers competitive plastic injection molding pricing in HCMC, optimized especially for:

– High-volume orders

– Products with recurring production cycles

– Businesses requiring continuous manufacturing runs

Pricing is provided transparently, based on: material type, mold complexity, production cycle time, and volume.

PLASTIC INJECTION MOLDING PROCESS AT ZENG HSING

We implement a standardized 6-step injection molding process in HCMC, ensuring controlled production and reduced lead times:

♦ S1. Requirement Intake and Solution Consultation

Our team analyzes requirements, suggests suitable materials, determines product durability needs, and proposes an optimal manufacturing solution.

♦ S2. Mold Inspection and Design

Zeng Hsing supports the design or optimization of the mold to ensure:

• Stable injection cycle time

• Clean part ejection with minimal defects

• Optimized manufacturing costs

♦ S3. Appropriate Plastic Material Selection

We utilize high-grade virgin plastic resins: ABS, PP, PC, PA6, POM, TPR, etc., ensuring required mechanical properties and durability standards are met.

♦ S4. Automated Injection Molding Production

The injection molding machines operate according to precisely programmed parameters, guaranteeing dimensional consistency for every component.

♦ S5. Product Quality Inspection

Our QC team verifies:

• Dimensional Accuracy

• Color Consistency

• Surface Finish

• Mechanical Durability

♦ S6. Assembly and Delivery

Products are packaged according to customer specifications or are subjected to functional assembly (if requested by the client).

BENEFITS OF CHOOSING ZENG HSING AS YOUR INJECTION MOLDING PARTNER

When partnering with Zeng Hsing, businesses in Ho Chi Minh City gain the following advantages:

√ Fast Production – On-Time Delivery: Continuous operational capability ensures large orders are met within short lead times.

√ Stable Quality, Extremely Low Tolerance: The QC team monitors 100% of products leaving the production line.

√ Diverse Material Expertise – Suited for Multiple Industries: Zeng Hsing has experience handling materials ranging from engineering plastics to complex industrial polymers.

√ Full Turnkey Service (A–Z): We manage the entire process, from mold design → injection molding → assembly → packaging → delivery.

√ Reduced Production Costs for Businesses: Thanks to our large scale and the ability to self-supply certain components, our plastic injection molding pricing remains highly competitive.

CONTACT ZENG HSING FOR PLASTIC INJECTION MOLDING IN HO CHI MINH CITY

If your business is seeking a reliable, high-quality plastic injection molding contractor in Ho Chi Minh City, capable of producing high volumes at a competitive price, Zeng Hsing is the perfect choice. We are committed to providing an optimal plastic manufacturing solution-helping your business reduce lead times, save costs, and create products that meet international standards.

ZENG HSING VIET NAM

Address: 28 VSIP II-A, No.28 street, KCN VSIP II-A, Vinh Tan ward, Ho Chi Minh city, Vietnam

Phone: (+84) 0355 846 965 (Mr. Nghia) – (+84) 0362 476 478 (Mr. Nam)

Email: nghia_duong@zenghsing.com.vn / nam_vu@zenghsing.com.vn

Website: zenghsing.vn

RELATED SEARCHES

Contract Plastic Injection Molding

Plastic Component Manufacturing Services

ABS Plastic Machining