As Vietnam’s industrial landscape continues to evolve, the demand for high-precision and durable aluminum components is surging. Aluminum die casting has emerged as the optimal solution for sectors such as automotive manufacturing, electronics, and industrial equipment. Choosing a reputable partner who offers competitive pricing and high-quality standards is essential to cost savings, production efficiency, and superior product integrity. Zeng Hsing is proud to be a trusted provider, delivering world-class aluminum die casting services tailored to meet all technical requirements in the Vietnamese market.

What is Aluminum Die Casting and Its Key Advantages?

High-Pressure Die Casting (HPDC) is a manufacturing process in which molten aluminum alloy is injected into a steel mold (die) under high pressure. This pressure is maintained until the metal completely solidifies. This method is ideal for creating components with complex geometries, smooth surface finishes, and high dimensional accuracy.

Outstanding Advantages of Aluminum Die Casting:

• High Precision: Produces components with tight tolerances, significantly reducing the need for post-casting machining costs.

• Thin Walls & Lightweight: Allows for the production of thin-walled parts, which saves material and reduces the overall weight of the product without sacrificing strength.

• Rapid Mass Production: Features short cycle times, making it the perfect solution for high-volume orders and fast-paced production schedules.

• Stable Mechanical Properties: Cast parts exhibit excellent structural integrity and strength, meeting rigorous industrial standards.

• Superior Surface Finish: Delivers smooth surfaces that are easy to paint, plate, or anodize, satisfying both aesthetic and technical requirements.

Thanks to these advantages, aluminum die casting in Vietnam is widely applied across modern industries, ranging from automotive and electronics to household appliances and precision engineering.

>>>> Xem thêm: Nhà máy ép nhôm áp lực TPHCM – Sản phẩm chính xác, chất lượng

Advanced Technology and Modern Production Lines at Zeng Hsing

Zeng Hsing stands as a reputable leader in Vietnam’s aluminum die casting industry, featuring state-of-the-art technology and professional manufacturing workflows. Our facility is equipped with:

– High-Performance Die Casting Machines: Utilizing world-class machinery from brands such as Toshiba and Shibaura, ensuring every component reaches peak precision and absolute stability.

– Automated Production Lines: Fully automated systems for material handling, injection, cooling, and quality inspection, which minimize human error and maximize productivity.

– Post-Casting CNC Machining: Beyond casting, we offer high-precision CNC machining and comprehensive surface treatments, including grinding, sandblasting, powder coating, plating, and anodizing to meet all technical specifications.

– Strict Quality Control System: A rigorous monitoring system ensures every finished product meets international standards for mechanical properties, tolerances, porosity levels, and aesthetic finish.

Equipped with advanced technology, Zeng Hsing is capable of manufacturing complex custom components, ranging from miniature intricate parts to large-scale industrial assemblies across various industries.

>>>> Xem thêm: Nhận gia công ép nhựa TPHCM số lượng lớn, độ chính xác cao

Manufacturing Process & Quality Control for Aluminum Die Casting

At Zeng Hsing, our aluminum die casting process in Vietnam follows a rigorous workflow to ensure every product meets premium quality standards:

• Mold Preparation & Part Design: Steel dies are precision-machined, lubricated, and thoroughly inspected before production to ensure structural integrity and flawless surface release.

• Melting & Metal Treatment: Aluminum alloys are heated to optimal temperatures, followed by degassing and impurity removal (fluxing) to ensure a high-purity, homogenous melt.

• Pressure Injection & Dwell Time: The molten metal is injected into the mold at high velocity and high pressure. This pressure is maintained (dwell time) until the metal is fully solidified.

• Solidification & Ejection: Once the component reaches the required structural hardness, the mold opens, and the part is carefully ejected.

• Machining & Finishing: This final stage includes deflashing (removing excess material), precision CNC machining, surface treatments, and a comprehensive final quality inspection.

The quality control system for aluminum die casting at Zeng Hsing (Vietnam) utilizes state-of-the-art measurement and inspection equipment, including CMM, Ultrasonic testing, and Industrial CT scanning. This ensures that every component strictly adheres to technical specifications and exceeds customer requirements.

>>>> Xem thêm: Đơn vị gia công chế tạo khuôn nhựa chính xác chất lượng cao

Alloys and Practical Applications

Zeng Hsing utilizes the most popular aluminum alloys in the die casting industry to ensure optimal performance for every project:

– ADC12 / A380 / A356: selected for their excellent castability, stable mechanical properties, and high versatility across a wide range of products.

– Practical Applications:

• Automotive Industry: Gearbox housings, oil pump assemblies, and engine brackets.

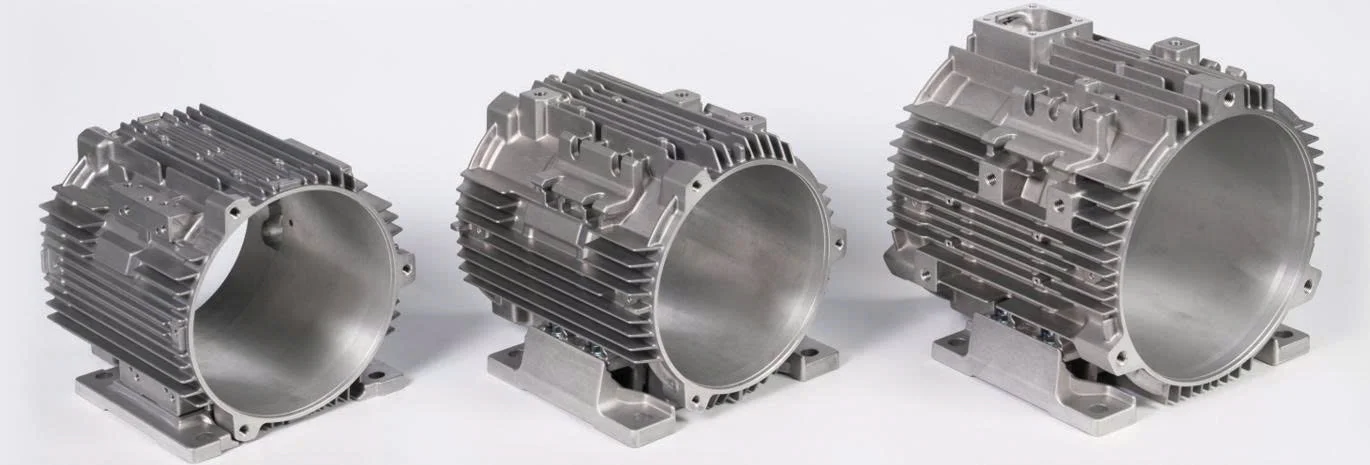

• Electrical & Electronics: Motor housings, electrical equipment enclosures, and high-efficiency heat sinks.

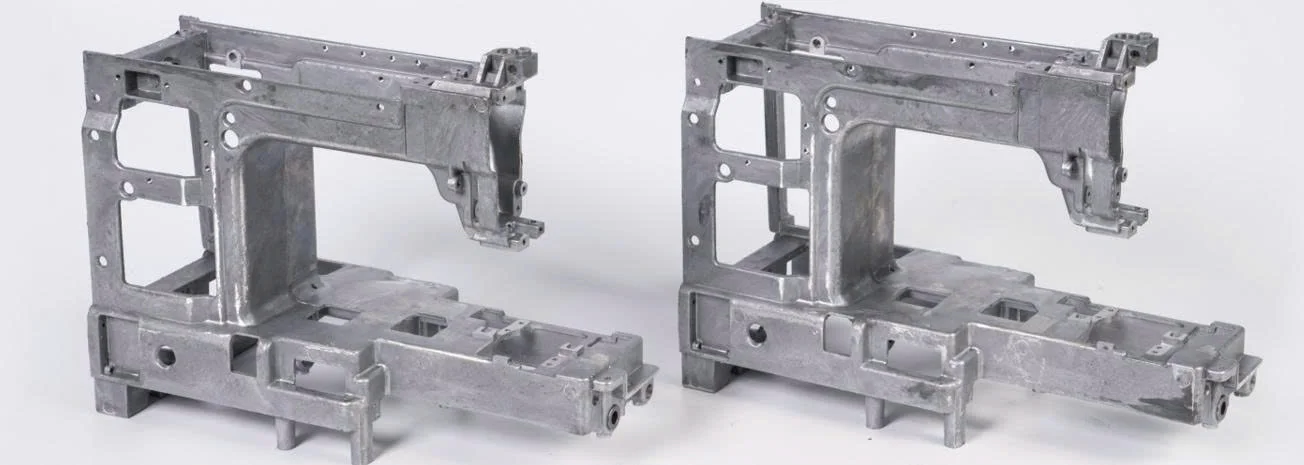

• Home Appliances & Precision Engineering: Sewing machine frames, mechanical components, and intricate aluminum parts.

By cooperating with Zeng Hsing—a reputable aluminum die casting partner in Vietnam—customers are guaranteed high-quality products, strictly met deadlines, and optimized cost-efficiency.

Commitment to Competitive Pricing and Professional Services

As a reputable leader in aluminum die casting in Vietnam, Zeng Hsing is committed to delivering highly competitive pricing through mass production efficiency, process optimization, and stringent material control. Beyond manufacturing, we provide comprehensive technical consultancy services:

– We assist in refining part designs to optimize them specifically for the high-pressure die casting process, reducing defects and costs.

– Expert guidance on selecting the ideal aluminum alloys, machining methods, and surface treatments tailored to your specific functional requirements.

– We provide transparent quotations and prioritize sustainable cooperation by consistently ensuring product quality and on-time delivery.

Contact the Leading Aluminum Die Casting Partner in Vietnam Today

Choosing a high-quality, cost-effective partner like Zeng Hsing is the strategic solution for businesses looking to reduce costs, guarantee product integrity, and optimize production lead times. Contact Zeng Hsing today for a comprehensive consultation, fast quotation, and the most efficient manufacturing solutions for all your die-casting needs—from motor housings, gearboxes, and heat sinks to specialized industrial and household components.

ZENG HSING VIET NAM

Address: 28 VSIP II-A, No.28 street, KCN VSIP II-A, Vinh Tan ward, Ho Chi Minh city, Vietnam

Phone: (+84) 0355 846 965 (Mr. Nghia) – (+84) 0362 476 478 (Mr. Nam)

Email: nghia_duong@zenghsing.com.vn / nam_vu@zenghsing.com.vn

Website: zenghsing.vn

Tìm kiếm có liên quan

Đúc nhôm áp lực hcm

Công ty đúc nhôm áp lực

Đúc nhôm theo yêu cầu

Xưởng đúc nhôm